News

Understanding the Mechanics: How 3-Jaw Scroll Chucks Work

When it comes to machining operations, having a reliable and efficient chuck is crucial. One such chuck that is widely used in the industry is the 3-Jaw Scroll Chuck. In this blog post, we will explore the mechanics behind these chucks and understand how they work to securely hold workpieces in place during machining operations.

The Basics of 3-Jaw Scroll Chucks

A 3-Jaw Scroll Chuck consists of three jaws that are evenly spaced around a central scroll plate. The scroll plate has a spiral groove that engages with the jaws, allowing them to move simultaneously towards or away from the center of the chuck. This movement is controlled by a key or wrench that rotates the scroll plate, causing the jaws to either close or open.

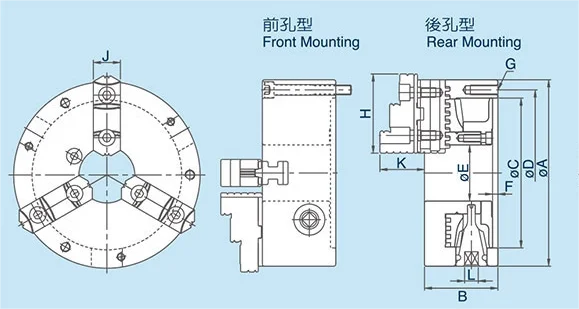

The Component of 3-Jaw Scroll Chuck

The scroll plate is a crucial component of the 3-Jaw Scroll Chuck. It is responsible for transmitting the rotational motion from the key or wrench to the jaws. The scroll plate has a spiral groove that matches the shape of the jaws. As the scroll plate rotates, it pushes or pulls the jaws, causing them to move inwards or outwards.

The Movement of the Jaws

The jaws of a 3-Jaw Scroll Chuck move simultaneously towards or away from the center of the chuck. This movement is synchronized by the scroll plate. When the scroll plate is rotated clockwise, the jaws move towards the center, gripping the workpiece. Conversely, when the scroll plate is rotated counterclockwise, the jaws move away from the center, releasing the workpiece.

Gripping Force and Accuracy

One of the key advantages of 3-Jaw Scroll Chucks is their ability to provide a strong and reliable gripping force. The spiral groove on the scroll plate ensures that the jaws move in a synchronized manner, resulting in equal pressure being applied to the workpiece. This provides a secure grip, minimizing the chances of slippage during machining operations. Additionally, the design of the jaws allows for self-centering, ensuring accurate positioning of the workpiece.

Adjusting the Chuck

To accommodate different workpiece sizes, 3-Jaw Scroll Chucks can be adjusted. This is done by rotating the scroll plate using a key or wrench. By rotating the scroll plate in one direction, the jaws move inwards, reducing the chuck's diameter. Conversely, rotating the scroll plate in the opposite direction causes the jaws to move outwards, increasing the chuck's diameter. This adjustability makes 3-Jaw Scroll Chucks versatile and suitable for a wide range of workpiece sizes.

Advantages and Limitations

3-Jaw Scroll Chucks offer several advantages, such as ease of use, self-centering capability, and strong gripping force. They are commonly used in applications where quick and repetitive workpiece changes are required. However, it is important to note that 3-Jaw Scroll Chucks may not be suitable for all machining operations. For example, when high precision is required, a 4-Jaw Independent Chuck might be a better choice, as it allows for individual adjustment of each jaw.

Conclusion

In conclusion, understanding the mechanics of 3-Jaw Scroll Chucks is essential for any machinist. These chucks provide a reliable and efficient way to hold workpieces during machining operations. By grasping the basics of how the scroll plate and jaws work together, one can make the most of these chucks and achieve accurate and precise results.

What Are The Industrial Applications of 3-Jaw Scroll Chucks

Related to recommend